Aquatic Industrial Lamps IP65

IP65 emergency industrial lamps: reliable lighting in any conditions

IP65 emergency lamps are indispensable assistants in various industrial facilities. Imagine a plant, a warehouse or even an underground tunnel - wherever reliable and uninterrupted lighting is required, even with sudden power outages, these lamps play a key role. It is important to note that the IP65 protection index guarantees that they withstand the effects of moisture and dust, which makes them ideal for work in difficult conditions.

The selection of the IP65 emergency lamp: what to pay attention to

When choosing an IP65 emergency lamp, several important aspects must be taken into account. First of all, this is the lighting power that should be sufficient to ensure the safety and comfort of personnel. It is also important to pay attention to the battery time - how much time the lamp will be able to shine from its own battery after the electricity is turned off. The location of the lamp is no less significant: in an open warehouse or in a closed room - this will affect the requirements for its placement and type of dispersion of light. And, of course, pay attention to the convenience of maintenance and replacement of lamps - the simpler these operations, the less risk of downtime and repair costs.

Advantages of emergency lamps IP65

One of the main advantages of these lamps is their high reliability. They are able to withstand significant changes in temperature, humidity and mechanical influences. This is especially important for industrial premises where working conditions are often unpredictable. It is also important to emphasize that emergency lighting ensures the safety of employees, preventing injuries due to lack of visibility at critical moments. The rapid inclusion of emergency light in the case of disconnecting electricity will significantly accelerate the evacuation of people from dangerous areas.

Practical advice on using

The correct installation of emergency lamps IP65 is the key to their effective operation. You should take into account the recommendations of the manufacturer on installation, paying attention to the type of fastening and wire. Regular maintenance, including checking the status of the battery and the integrity of the lamps, ensures uninterrupted operation of emergency lighting. Periodic verification of lamps for performance, as well as training of personnel on the use of emergency lamps, is important to ensure the continuous operation of the enterprise. This will minimize the risk of emergency situations and maintain production.

AppropriateProducts

Corresponding products

The best soldproducts

The best -selling products-

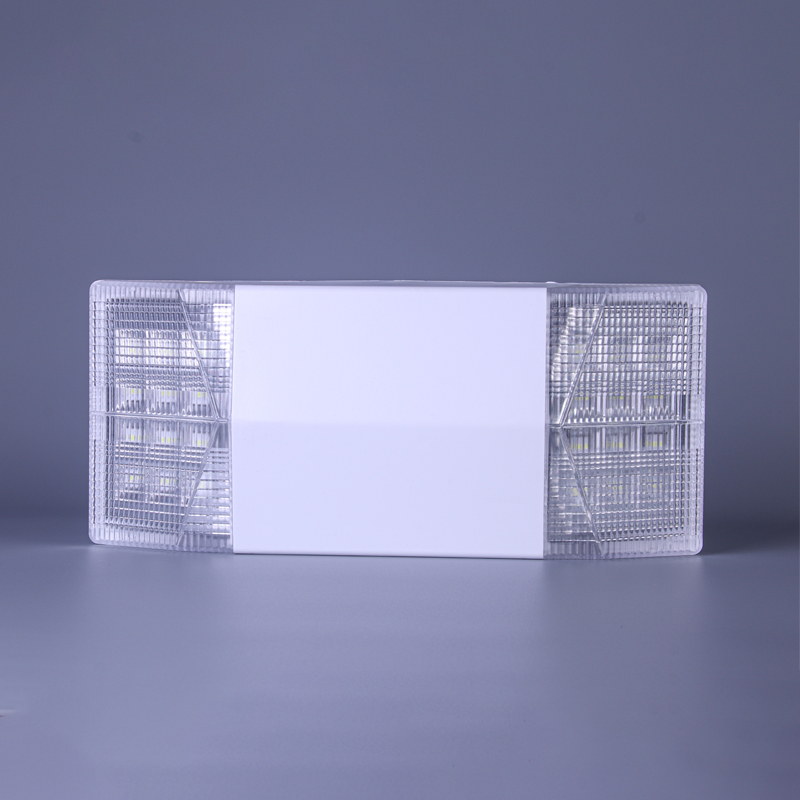

6W LED rechargeable automatic emergency lamp

6W LED rechargeable automatic emergency lamp -

Explosion -proof LED emergency lamp

Explosion -proof LED emergency lamp -

LED emergency lanterns with a double head 9 watts

LED emergency lanterns with a double head 9 watts -

IP65 3W/6W/8W rechargeable SMD LED automatic emergency lamp

IP65 3W/6W/8W rechargeable SMD LED automatic emergency lamp -

Wall ABS Red LED emergency exit with the battery

Wall ABS Red LED emergency exit with the battery -

Lithium battery of 80 LEDs Emergency LED lamp

Lithium battery of 80 LEDs Emergency LED lamp -

3 watts rechargeable Avaritic light emergency emergency emergency

3 watts rechargeable Avaritic light emergency emergency emergency -

LED emergency two -headed lantern on the battery 6 W

LED emergency two -headed lantern on the battery 6 W -

LED rechargeable emergency sign of output light of emergency light box Box

LED rechargeable emergency sign of output light of emergency light box Box -

Portable battery -free LED lamp for 60 LEDs

Portable battery -free LED lamp for 60 LEDs -

LED rechargeable emergency lamp with a capacity of 6 watts

LED rechargeable emergency lamp with a capacity of 6 watts -

9 W LED automatic two -headed emergency lanterns

9 W LED automatic two -headed emergency lanterns

Connectedsearch

Related search- China Emergency Lighting 6W Factory

- Emergency lamp rating

- what lamps for emergency lighting

- China Emergency Lights of the Factory

- China emergency power source for factories lamps

- China waterproof LED emergency lighting suppliers

- China manufacturer of these emergency lights

- Luminer Emergency LED IP20

- China manufacturer Built -in Battery Emergency Lights

- Suppliers of reliable emergency lamps from China